FCA 22 LCPM FF

22KW 23-76 CFM VSD COMPRESSOR WITH TANK DRYER & FILTERS.

Born for laser cutting applications!

- Compressor type - 1:1 Direct Drive Variable Speed Screw

- Use - Continuous

- Noise level - 70dBa

- Working pressure - 15 Bar

- Air delivery - 23-76cfm

- Power - 22kW/30HP

- Electric - 400V/3Ph/50Hz

- Warranty - 1 Year

Forward compressors provide you with reliable and continual compressed air for various compressed air application and industrial demands, with its imperial rigorous design concept from Europe. One key start & Stop: simple and stable opperation Intelligent contol system: real time monitoring operation status, including function of self-service reminder and fault inspection alarm, a friendly experience of human-machine interface Concise layout internally: for easier maintenance and less service time.

Laser cutting air compressor application.

Compared with gas cutting, plasma cutting, die punching, sawing, wire cutting, water cutting, EDM and other traditional cutting processes, with cutting speed, small slit, high cutting accuracy, small material deformation, economic and other advantages, shearing machine and other traditional cutting equipment will be gradually replaced by laser cutting machine.

In the process of laser cutting, the compressed air plays a key role in promoting combustion and heat dissipation while blowing the melted liquid away from the material and protecting the lens. If the oil content and water content of the compressed air are high, water and oil accumulate on the surface of the lens, affecting the transmission of the laser beam, causing

the focus to disperse, resulting in poor roughness and even sub-quality output. There is also the risk of damaging the lens and burning the laser head, greatly reducing the lifetime of the laser cutting machine and increasing operating costs. Therefore, the pressure, oil content, water content of compressed air and the stability of machine have high requirements, our

products are tailored to the application requirements of laser cutting.

Features:

- All-in-one air solution designed for laser cutting process

- Compact turn-key compressor, dryer, filters and air tank package.

- Innovation technology air cooled permanent magnet motor.

- 1:1 directly drive to the airend design, enhance minimum transmission chemical loss

- Inverter - Strict selection based on the verification from market industry applications

- Smart inverter detects the compressor air needs in real time - Quick respondence to the regulation system for perfect match every time.

- Extra large surface cooler, allow maximum 46 oC ambient environment use.

- Thermostatic control cooling fan, efficiently prevents over-cooling and condensate.

- Latest generation design air end. High precision manufacturing process. Results in high performance compressor air delivery.

- 15 bar outlet pressure capability.

- Fully sealed cabinet with soundproofing and noise-reducing partitions to minimize noise.

- Hose and hard tube connection, with high temperature & pressure resistant hose and O rings, a fully rigid and stable structure design.

- Multi-function electronic controller. One key press to switch on/off

- Self-service timing management

- Self-protection at fault: auto-stop and check, instant alarm at the same time.

- Pre Filtering. Allows the maximum volume air inlet at the minimum pressure drop. Slot design enables quick removal for regular cleaning.

- Compliant with Australian Workplace Health and Safety Regulations

Benefits:

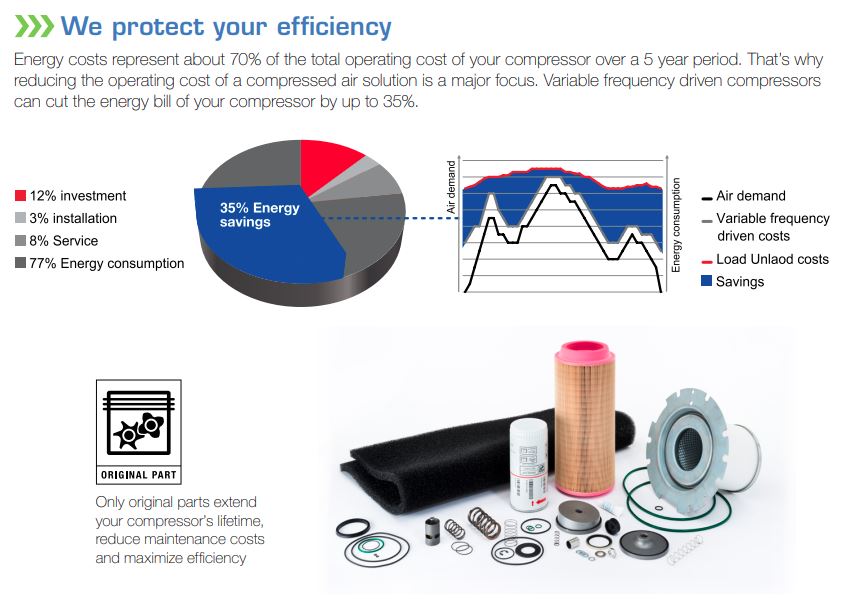

Up to 35% costs savings On your energy bills.

Get a return on investment in as little as 2 years (depending on circumstances)

| SKU | FCA22LCPMFF |

| Brand | Forward Compressors |

| Shipping Weight | 657.0000kg |

| Shipping Width | 2.000m |

| Shipping Height | 2.100m |

| Shipping Length | 0.920m |

| Shipping Cubic | 3.864000000m3 |

Calculate Shipping

Flat Rate to Metro Areas.

Be The First To Review This Product!

Help other Airgen Australia users shop smarter by writing reviews for products you have purchased.